The processing and development of precision molds is inseparable from those who learn advanced processing technology and equipment. The main processing technologies of precision mold processing include CNC milling, wire cutting, EDM, grinder, lathe, measurement and so on.

1. CNC Milling

From traditional ordinary milling machines to three-axis machining centers, to five-axis high-speed milling, it can process very complex three-dimensional complex surfaces, and is less and less limited by the hardness of materials.

2. Slow-moving wire cutting processing

Slow wire cutting is mainly used for the processing of 2D and 3D linear parts such as various stamping dies, plastic dies, powder metallurgy dies, etc. In injection mold manufacturing, common applications include insert holes, ejector holes, lifter holes, cavity clearance angles, and sliders.

3. EDM

EDM is suitable for the processing of complex parts such as precision small cavities, narrow slits, grooves and corners. When tools are difficult to machine to complex surfaces, deep cuts are required, and the aspect ratio is particularly high, EDM is preferred over milling. Milling electrode re-discharge improves success rate and is more suitable for EDM than expensive tool cost.

4. Grinding machine processing

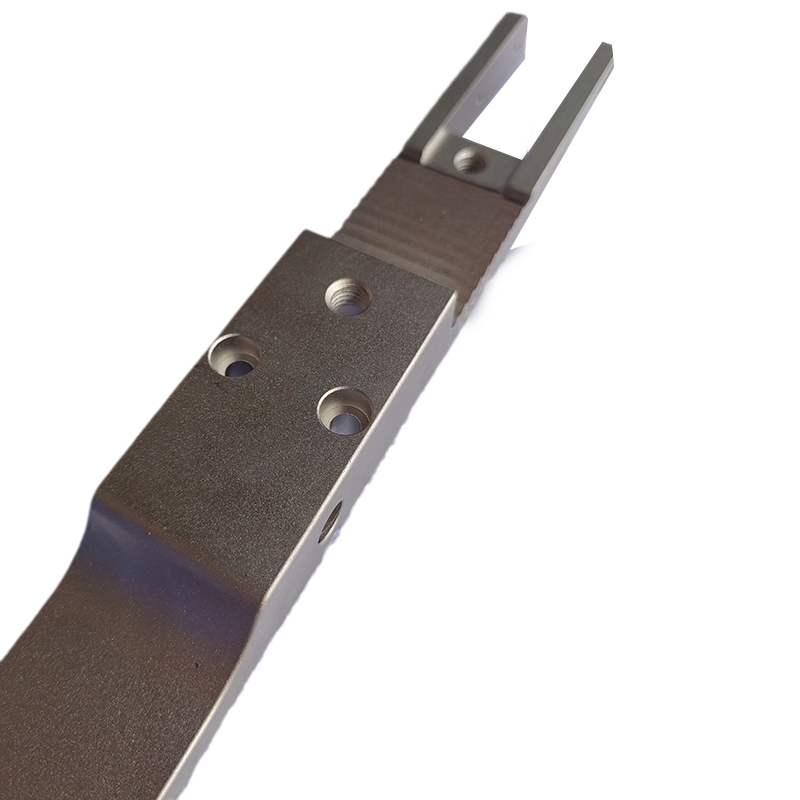

Grinding machine is a kind of equipment for precision machining the surface of parts, especially for work hardening parts. Surface grinder, universal internal and external cylindrical grinder, coordinate grinder (pg optical curve grinder) are the main grinders used in mold processing.

The small flat grinder is mainly used to process small mold parts, such as precision inserts, precision mold cores, sliders, etc. Large water mills are often used to process large size templates. The linear speed of the grinding wheel of the surface grinder and the high-speed movement of the table have become the general trend. With the adoption of advanced functional component technologies such as linear guides, linear motors, and static pressure screws, the movement speed has been greatly improved, and the grinding wheel dressing technology has also been continuously improved.

5. CNC lathe

CNC lathes are also commonly used processing equipment in injection mold workshops. The complex-shaped rotary body can be easily realized through programming at the same time, and the machine tool can automatically change the tool, which greatly improves the production efficiency of the mold. The machining accuracy and manufacturing information technology problems of CNC lathes are becoming more and more perfect.

6. Measuring instruments

High-precision measurement equipment plays an important role in the early stages of precision plastic mold design, from digital mapping to mold process measurement, to mold acceptance measurement and mold repair measurement.

24-hour service hotline:

24-hour service hotline:

24-hour service hotline:

24-hour service hotline: